Hybrid Battery Technology: In Memory & in Honor of Dave Hermance

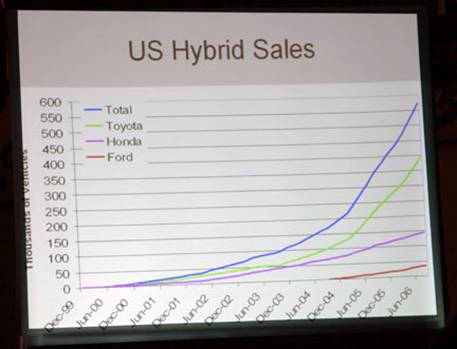

Toyota is the world’s dominant auto manufacturer of hybrid vehicles. Other major auto manufacturers use Toyota’s technology.

In his capacity as ‘Executive Engineer for Advanced Technology Vehicles’ at the Toyota Technical Center (TTC) in Gardena, California, Dave Hermance was a walking resource on this technology. He was also an enthusiastic advocate for hybrid automotive technology and Toyota’s Prius in America.

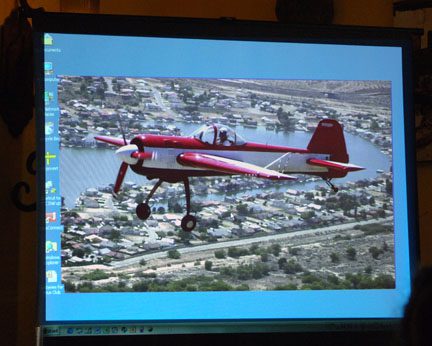

In his spare time Dave enjoyed flying. On Saturday, November 25, while performing aerobatic maneuvers in his experimental Interavia E-3 aircraft just off of the Southern California coastline, he crashed and perished in the Pacific Ocean. The news came as a shock to me and many others. He has left a void that will be difficult to fill.

Dave had worked for Toyota since 1991, and before that with General Motors since 1965. He had earned wide recognition as an authority on Toyota’s hybrid vehicles in particular, and about green vehicles industry-wide in general. Perform a Yahoo search on “Dave Hermance” and page after page of links to presentations that he made will appear.

However, Dave was much more than an experienced automotive engineer. He was also a nice and surprisingly humble guy, given his public stature. He was easy to talk to and very accessible. He took time to answer everyone’s questions and he seemed genuinely interested in listening to what others had to say. It was fitting, given his role regarding alternative energy vehicles, that he seemed to have an endless supply of energy which he used to spread the word.

I met Dave on one of his speaking engagements at a Prius Club of San Diego (www.priusclubsd.com) meeting, and I reported on what he had to say about hybrid technology in a two-part AutoMatters column (see https://automatters.net/2004%20Columns/0130.htm and https://automatters.net/2004%20Columns/131.htm on the www.AutoMatters.net Web site). I recommended him as a speaker to the Motor Press Guild, and they invited him to give a presentation.+

It was just last month that Dave made another drive from his home in Huntington Beach on one of his weekend days off to speak to the Prius Club of San Diego again. I covered that presentation but had not written about it yet due to other, more time-sensitive events. They can wait…

* * *

Due to the interest in plug-in, rechargeable hybrid vehicles, and the fact that the battery pack is the single most expensive component that differentiates hybrids from non-hybrid vehicles, this time Dave chose to speak to us on the state of battery technology.

Batteries can be divided into two groups: primary and secondary. Primary batteries are not rechargeable. Secondary batteries are rechargeable. Primary batteries are the largest component of the battery business.

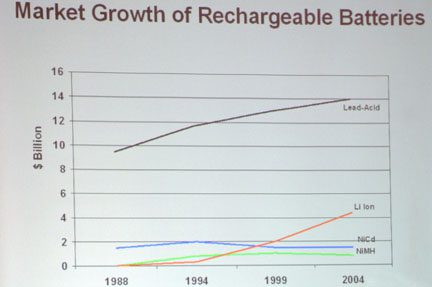

The battery business is huge: $34 billion in 2004 and growing. Of that, the principal batteries in the world market are lead-acid ($14 billion). A big chunk of those are for fork lifts, which use huge packs of lead-acid batteries ganged together. That industry likes lead-acid batteries, in part because they are so heavy that they act as counter-weights for the loads lifted. In automotive applications, the quantity of lead-acid batteries used continues to increase because there are more and more vehicles on the road.

On the other end of the chemistry scale from lead-acid are zinc-manganese oxide batteries or, as Dave said, “Energizer bunny” batteries – the primary batteries used as throwaways in kids’ toys and all sorts of other consumer electronics devices.

Portable rechargeable batteries, like those used in power tools and cell phones, also make up a significant segment of the battery business, followed by specialty batteries with some very exotic chemistries for use in the defense and other industries.

Lithium is now the third-highest battery chemistry in terms of sales. Lithium Ion (Li Ion) is the technology showing real growth in the market and a lot of money is being spent on Lithium Ion chemistries (not only by battery companies but also by car companies). That is the dominant technology for use in cell phones, laptop computers and almost anything that uses a rechargeable battery. It has begun to replace Nickel Metal Hydride (NiMH), of which a subset is hybrid vehicle batteries. In contrast to Lithium, this type represents less than a billion dollars per year and its volume is decreasing. Today Lithium Ion is less expensive than Nickel Metal Hydride because the price of nickel, in large part due to its demand by China for use in stainless steel alloys, has gone up by a factor of three in the last five years.

Lithium Manganese Oxide batteries have a fairly limited life span.

Lithium Nickel, alloyed with either cobalt or aluminum, also has problems that need to be solved. Lithium is a volatile, potentially unstable material. While that characteristic makes it a good battery candidate, it also has been responsible for some unresolved safety concerns, including some well-publicized fire issues that included laptop computers at charge and overcharge conditions. In order for this to be safe in a vehicle application, other technology will be needed beyond the battery. It will require active safety systems.

The new player in the market is Lithium Iron Phosphate, which is an intrinsically safe chemistry because it doesn’t have this exothermic temperature runaway on charge or overcharge. A problem is that is does not store much more energy than Nickel Metal Hydride.

When battery companies are asked to develop specific batteries for hybrid vehicles, it is important to remember that these applications still represent a relatively small portion of the total battery market. Auto manufacturers do not have a lot of leverage because of that. Furthermore, since Nickel Metal Hydride is on a decline, it is probably getting to be time to change battery chemistries. That is why Toyota has gotten into the battery business and is working on research and development of Lithium battery chemistries.

A battery’s price is based on its energy storage capability (in kilowatt hours). Generally the bigger a battery’s storage capacity, the more expensive it is. On a hybrid vehicle like the Prius, add to that the cost of the battery packaging, the control system plus mark-up for profit and you have an end price of around $3,000.

Lead-Acid is really cheap but it does not last very long, so it is not good for hybrid vehicle applications like in the Prius. Preferably the batteries would last as long as the vehicle.

In a hybrid vehicle, and this is important, it is not necessary to store the most possible energy in the batteries. Instead, as Dave explained, in hybrids “most of the energy is stored in gasoline, so what we really want in a vehicle application is lots of power. We use the batteries in a hybrid application as a power buffer to supplement the output of the gasoline engine where it’s inefficient. We don’t need to store a lot of energy because we’ve got gasoline on board.”

“There is a trade-off between power and energy within any given chemistry. Not all Nickel Metal Hydride batteries are the same. Not all Lithium Ion batteries are the same. It depends on what application you’re going to use the battery in, how you customize by changing very subtly the elements that you use in the battery to change whether they store more energy or whether they’re able to deliver lots of power. And so, that’s a balance that you play.” In contrast, in consumer electronics applications the power demand is relatively low and constant, but since the batteries are the only source of stored energy, storage capacity is the priority.

Another factor is the duty cycle. In consumer electronics, you charge the battery all the way to the top and then discharge it all the way to the bottom. Yet the worst things you can do to degrade the condition of these batteries, because of their chemistry, is let them get hot, charge them up to within the top 10% of charge, and discharge them to within the bottom 10% of charge. As a result, the life of batteries in these applications is typically less than a thousand cycles. If you can keep the state of charge of the battery in the middle it lives a lot better.

Obviously a life of a thousand cycles will not work for a car that you may keep for many years. The duty cycle of the Prius’ Nickel Metal Hydride batteries is such that they operate in a state-of-charge from 45% to 75% (the “sweet spot”). Therefore, due to its design, you will experience hundreds of thousands of 5% cycles and hundred-to-zero cycles (note that the graph on the Prius’ in-car display is showing usable state-of-charge, not actual state of charge).

Other concerns include heat dissipation (so different designs of vehicles may have different battery packaging) and battery power at low and high temperatures. In cold climates Toyota (and Lexus) do “not tap the battery cold” because that would damage the battery. Once the cabin air is heated, the batteries can be used again. The reverse applies to high temperature situations and cooling the cabin air. Regenerative energy is not stored when the batteries are really hot (as a side note, plug-in batteries will not take a charge if they are too hot). The highest priority in Prius’ control system is to preserve battery life, so it will alter the way it uses the batteries depending upon temperature or state-of-charge in order to preserve battery life.

So, how long will a set of Prius batteries last before they have to be replaced? Toyota is confident that based on cycle life they will last the equivalent of 180,000 miles. However, actual calendar life is still somewhat of a mystery because testing cannot accelerate the passage of time.

What can we look forward to in battery technology, and when? One estimate has Lithium batteries that are based on existing consumer electronics batteries hitting the market in 2008, followed by a period of continuing development. However, Dave said “we won’t release the Lithium until it is a good battery.” “Toyota … made … (its) reputation in the United States on durability, reliability and dependability, and we are not going to compromise that (by) being the first on our block to have a new chemistry. It will be good when we bring it in.”

Even further on the horizon are pioneering efforts by some small startup companies that are developing nano technology batteries for the market. These use Lithium Iron Phosphate chemistries and may be trading off some energy storage capacity for safety and big cycle life.

The U.S. Department of Energy is interested in fostering development of plug-in hybrid vehicles, in order to reduce our oil consumption and diversify our transportation energy. Towards that end, in May they held a workshop to which 160 people were invited. Dave drew these conclusions from that workshop: Today oil fuels 98% of transportation energy. The other 2% is fueled by ethanol. The technical merit of plug-in technology is oil substitution – not air quality. Batteries are the key issue.

If there is a governmental “regulatory requirement that a vehicle has all-electric range from zero,” that will probably, at the very least, ”delay the introduction of the technology and (perhaps) kill it because you have to increase the size of the power electronics and the size of the drive motor to have an acceptable vehicle.” In contrast, a “blended” strategy that uses electricity to supplement gasoline energy will result in as much petroleum “displacement” without radically changing the design of the vehicle.

Another idea out there is called “vehicle to grid.” That would have drivers plug their vehicles into the power grid when they are not in use, so that utility companies could draw energy from them, as needed. A big problem with this idea is that it would add cycles to the vehicles’ batteries. Due to current rechargeable battery technology, that would reduce their useful lives.

Plug-in vehicles would require much more battery capacity than today’s hybrids: from a minimum of three to four times greater, to as much as eight to nine times greater. That would dramatically increase the already high price of the batteries, making the vehicles significantly more expensive than today’s hybrids. That would also have implications of increased weight and decreased interior volume.

Plug-in vehicles would typically run from a 100% state-of-charge down to 20%, which may affect safety on the fully-charged end and also reduce battery life expectancy. Plug-in vehicles would also require the creation of a recharging infrastructure.

People who are already critical of today’s published fuel economy numbers would no doubt be really skeptical of published fuel economy figures for plug-in vehicles. These will vary wildly, due to a number of variables. As you use up the charge in the batteries you will begin to use much more gasoline, causing the fuel economy numbers to change dramatically. How and where the vehicles are used will also have a significant effect on mileage.

Much work needs to be done to make plug-in hybrids a viable reality. Realistically it could be another five to eight years before these vehicles are available in any significant volume.

Afterwards Dave fielded questions. Regarding the possible use of ultra-capacitors, he said that these could not even store as much energy as the batteries in today’s Prius, they are expensive and they take up a lot of space. However, they might be good for use in conjunction with batteries. Some bus applications already do that to store the large and sudden amounts of energy recovered in their regenerative braking system.

As for a suggested revival of all-electric vehicles, Dave answered by telling us about the auto manufacturers’ last attempt. He said that during that time both Toyota and GM had an ample supply of vehicles available, but that there was virtually no demand for them because they did not meet the needs of drivers nearly as well as other vehicles on the market. Toyota’s EV sold at a rate of less than 300 vehicles per year. Not surprisingly, Toyota lost a lot of money on that project.

A question was asked about hybrid diesel electrics. Toyota has a hybrid diesel in a package delivery vehicle in Japan. Because the diesel engine is more thermodynamically efficient (42%) than the conventional gasoline engine (34%) and even the Atkinson cycle engine (38%) found in the Prius, a diesel hybrid is the most efficient hybrid of the three. However, the increase in efficiency is offset by the higher cost of diesel fuel and the higher cost of the diesel after-treatment required to meet U.S. emissions standards. Mercedes will probably bring such a vehicle to market within a few years because they are heavily invested in diesels for the European market.

Dave, you had a knack for making complex, technical material simple and easy for ordinary people like me to understand, and you presented it in a friendly, non-intimidating way. You’re really going to be missed.

Drive safely and do join me again next time.